- Ultimate Guide to Buying Your First Table Saw - June 4, 2025

- The Best Tool Brands – Are You Using the Right One? - May 30, 2025

- How to Build a Fire Pit in Just One Day - May 25, 2025

Based on my research, I now have comprehensive information about table saws, market statistics, safety features, buyer considerations, and pricing. I’ll create a detailed article following the instructions provided.

Ultimate Guide to Buying Your First Table Saw

The Table Saw Market is Booming – Here’s Why You Need to Act Now

Picture this: you’re staring at a piece of lumber, trying to make a perfect cut with a circular saw, and you realize you’re fighting a losing battle. The table saw market was valued at USD 733.81 Million in 2024 and is projected to reach USD 1080.05 Million by 2031, growing at a CAGR of 4.95%. This isn’t just another statistic – it’s proof that woodworkers everywhere are discovering what professionals have known for decades. When I started my woodworking journey, I made the classic mistake of thinking I could get by with just hand tools and a circular saw. Boy, was I wrong! The precision, safety, and efficiency that a quality table saw brings to your workshop is simply irreplaceable. The table saw market has experienced significant growth in recent years due to the increasing demand for woodworking tools and the rise in DIY projects. Whether you’re building your first coffee table or renovating an entire kitchen, the right table saw will transform how you approach every cut.

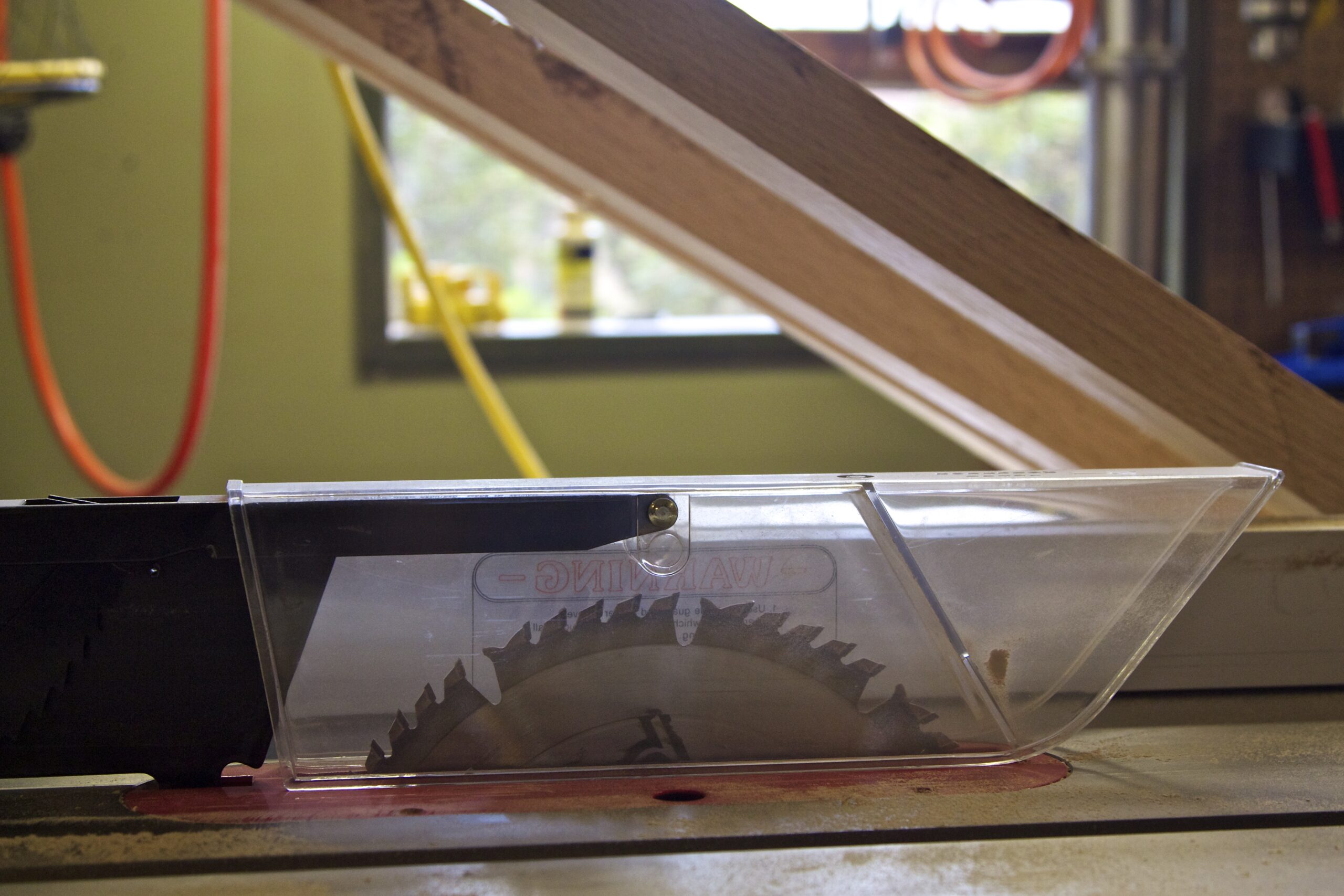

Understanding the Shocking Reality of Table Saw Injuries

Before we dive into the exciting world of table saw features, let’s address the elephant in the room – safety. Over 30,000 table saw injuries occur annually, with fingers and hands being the most frequently injured body part and lacerations being the most common injury. That’s roughly 82 people getting injured every single day! Even more alarming, about 4,000 result in amputations that can be career-ending for some professional carpenters and contractors. Medical costs for the treatment of table saw injuries are estimated at more than $2 billion every year. I’m not trying to scare you away from buying a table saw – quite the opposite! Understanding these risks empowers you to make smarter purchasing decisions and prioritize safety features that could literally save your fingers. The good news? Modern table saws come equipped with revolutionary safety technology that can turn a potential amputation into nothing more than a small nick.

Decoding Table Saw Types – Which One Matches Your Ambition

Walking into a tool store without knowing the different types of table saws is like trying to buy a car without knowing the difference between a sedan and an SUV. Benchtop table saws are small, portable saws that are ideal for small tasks and DIY projects, generally lightweight and can be placed on a workbench, while contractor table saws are designed for heavy-duty work, are more robust and come with rolling wheels for mobility, suitable for larger projects and more frequent use. Let me break this down in a way that actually makes sense. If you’re just starting out and working in a garage or small space, a benchtop saw might seem appealing because of its size and price. However, don’t let the compact form factor fool you – these can still pack serious cutting power. Cabinet table saws are stationary saws used primarily in cabinet and furniture-making shops, offering the highest level of precision and power, making them ideal for professional woodworkers. Think of cabinet saws as the luxury cars of the table saw world – they’re heavy, expensive, but absolutely incredible if you have the space and budget.

Power and Performance – The Heart of Every Great Cut

Here’s where things get interesting – the motor is essentially the soul of your table saw. Brett Labeka, expert handyperson for Frontdoor, recommends looking for a saw with at least 1.5 to two horsepower for home use. But here’s what they don’t tell you in the marketing brochures: more power isn’t always better if you can’t handle it properly. I learned this the hard way when I first tried using a friend’s 3-horsepower cabinet saw and nearly lost control during a kickback incident. Powerful motors draw between two and four amps of current, which can be enough to blow a breaker in your fuse box. You need to consider your workshop’s electrical setup before falling in love with that monster motor. The sweet spot for most home woodworkers is around 1.75 horsepower – enough power to cut through hardwoods confidently, but manageable enough that you won’t constantly trip your breaker or feel overwhelmed by the tool’s raw force.

The Fence System – Your Gateway to Professional Results

If the motor is the heart of a table saw, then the fence system is definitely the brain. “I’d say the fence is the most important thing to consider, whatever your budget is,” states Johnson. A mediocre fence will drive you absolutely crazy with inconsistent cuts and constant readjustments. “But for those on a tighter budget, I would recommend choosing a table saw with a rack and pinion fence for a more reliable alignment”. I cannot stress this enough – a good fence system will make you look like a master craftsman even if you’re just starting out. Look for fences that lock down securely without any play or wiggle. The fence must be sturdy and dead flat for accuracy, and should also be simple to adjust with an easy-to-read distance gauge and lock securely. When you’re shopping, actually test the fence mechanism – slide it back and forth, lock it down, and check for any movement. Your future self will thank you for being picky about this feature.

Blade Size and Cutting Capacity – Matching Your Saw to Your Projects

The blade size debate can get heated in woodworking circles, but let me give you the straight truth. Most table saws have 10-inch blades that cut as much as 3-½ inches deep at a 90-degree angle and 2-½” at a 45-degree angle. For most home projects, a 10-inch blade is the goldilocks zone – not too big, not too small, just right. Eight-and-a-quarter inch blades, found primarily on cordless saws, are lighter and allow for compact saw designs, however, they limit your ability to cut thicker stock and are not compatible with standard dado blades. Here’s a practical example: if you plan to build kitchen cabinets using 3/4-inch plywood, you’ll want that full 10-inch blade capacity. Ten-inch blades offer superior cut depth and are more suitable for cutting sheet goods, dimensional lumber, and hardwoods, and also support dado stacks for joinery and more advanced woodworking applications. The cutting capacity isn’t just about thickness – it’s about the flexibility to tackle unexpected projects without limitations.

Revolutionary Safety Technology That Could Save Your Fingers

This is where table saw technology gets truly exciting. The most advanced safety system currently available is offered by SawStop, where SawStop’s technology detects human skin and stops the blade within five milliseconds, drastically reducing the risk of serious injury. I’ll be honest – when I first heard about SawStop technology, I was skeptical. It seemed too good to be true. But then I watched a demonstration where they touched a hot dog to a spinning blade, and the saw stopped so fast that the hot dog barely got nicked. Social media is filled with stories from woodworkers who would have lost digits on other table saws but walked away from an incident with just a scratch, thanks to SawStop. The federal Consumer Product Safety Commission (CPSC) appears poised to mandate a SawStop-type safety brake on all new table saws sold in the United States. While SawStop saws do cost more upfront, consider this: the Consumer Product Safety Commission says that when a person is hospitalized, the societal cost per table saw injury exceeds $500,000 when you also factor in loss of income and pain and suffering.

Budget Considerations – Getting the Most Bang for Your Buck

Let’s talk money, because pretending budget doesn’t matter is just silly. When you consider the performance and feature set against the $269 price tag, Skil is an easy choice for us as the best budget table saw for DIY use. However, I’ve learned that with table saws, you really do get what you pay for most of the time. Entry-level saws can range from $200 to $600, while professional cabinet saws can easily exceed $3,000. Think about it this way: if you buy a $300 saw that frustrates you every time you use it, you’ll either stop woodworking or end up buying another saw anyway. DeWALT DWE7480 is an excellent table saw, especially if you consider its price, and it’s a step up from the highly popular DW745 and slightly more expensive, but the larger rip capacity and higher RPM are well worth the extra money. My advice? Buy the best saw you can reasonably afford, even if it means waiting and saving up a bit longer. A quality saw will grow with your skills and last for decades.