- Avoid a Holiday Disaster with These Quick Repairs - June 4, 2025

- “These 5 DIY Wood Projects Are Trending Like Crazy Right Now” - June 2, 2025

- The Lazy Person’s Guide to Home Maintenance - May 31, 2025

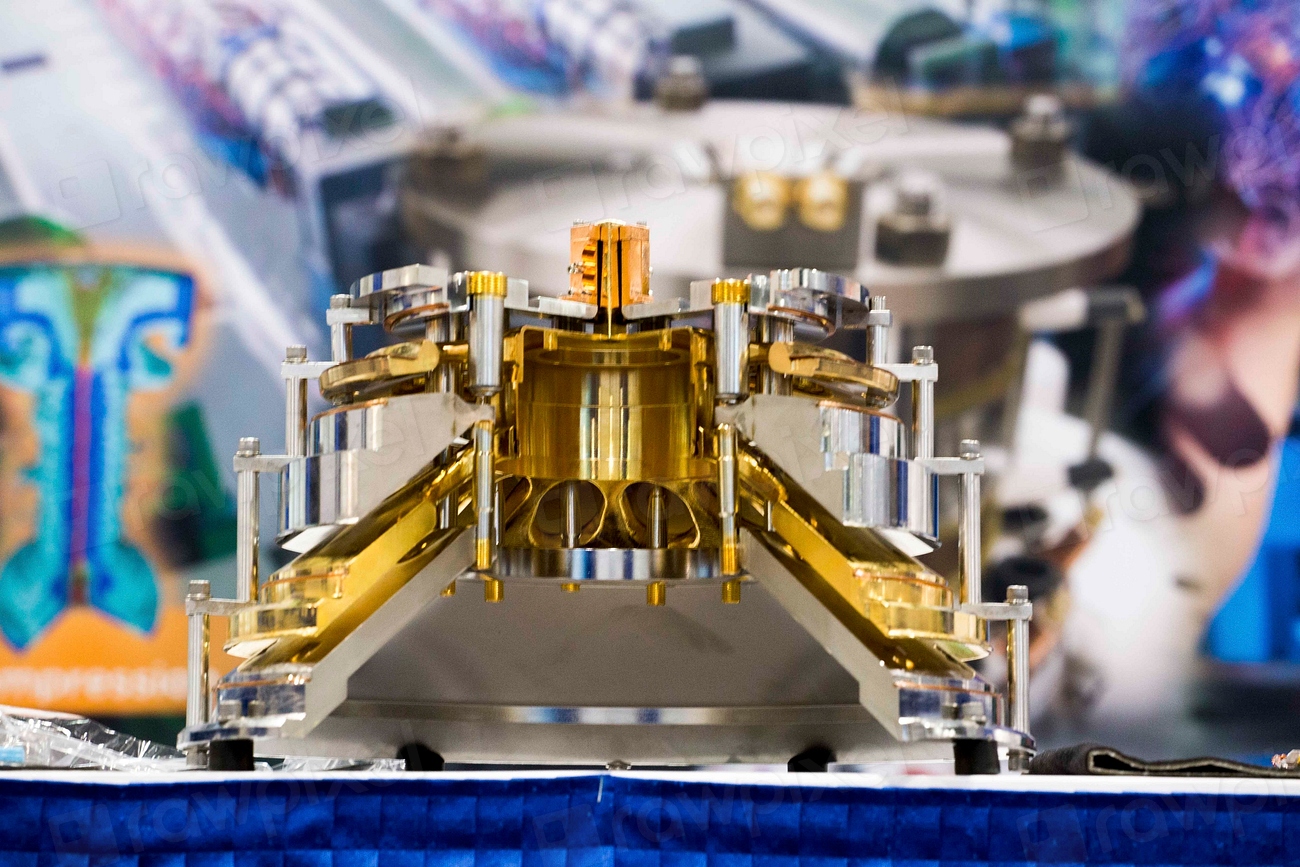

AI’s Surprising Leap into the World of Tools

Imagine holding a power tool that seems to think for itself—adapting, learning from your grip, and warning you before you make a mistake. This isn’t science fiction anymore. Artificial Intelligence (AI) is quickly carving out its place in the tool industry, turning ordinary gadgets into smart, responsive helpers. It’s not just about making fancy new products; it’s about a shift in how people work, create, and even repair things. The once simple hammer-and-nail world is suddenly buzzing with sensors, data, and algorithms that learn from every turn of the screw. This whirlwind of change is making many tool users—from DIY dads to factory engineers—sit up and wonder: just how far will AI go in transforming their daily grind?

Smart Tools Are Taking Over Workbenches

Walk into any modern hardware store and you’ll notice a new breed of tools—smart screwdrivers, drills, and wrenches that connect to your phone or adjust themselves automatically. Companies like Bosch and DeWalt have rolled out drills that sense the type of material and tweak torque settings on the fly. No more guessing or stripping screws. According to MarketsandMarkets, the global smart tools market is booming, expected to rocket from $3.5 billion in 2021 to $8.5 billion by 2026—a jaw-dropping 19.5% yearly growth rate. This explosion isn’t just about bells and whistles; it’s about making tools safer, faster, and more intuitive for everyone. Imagine your drill predicting when it’ll need maintenance, or your saw warning you about dull blades before they ruin your project.

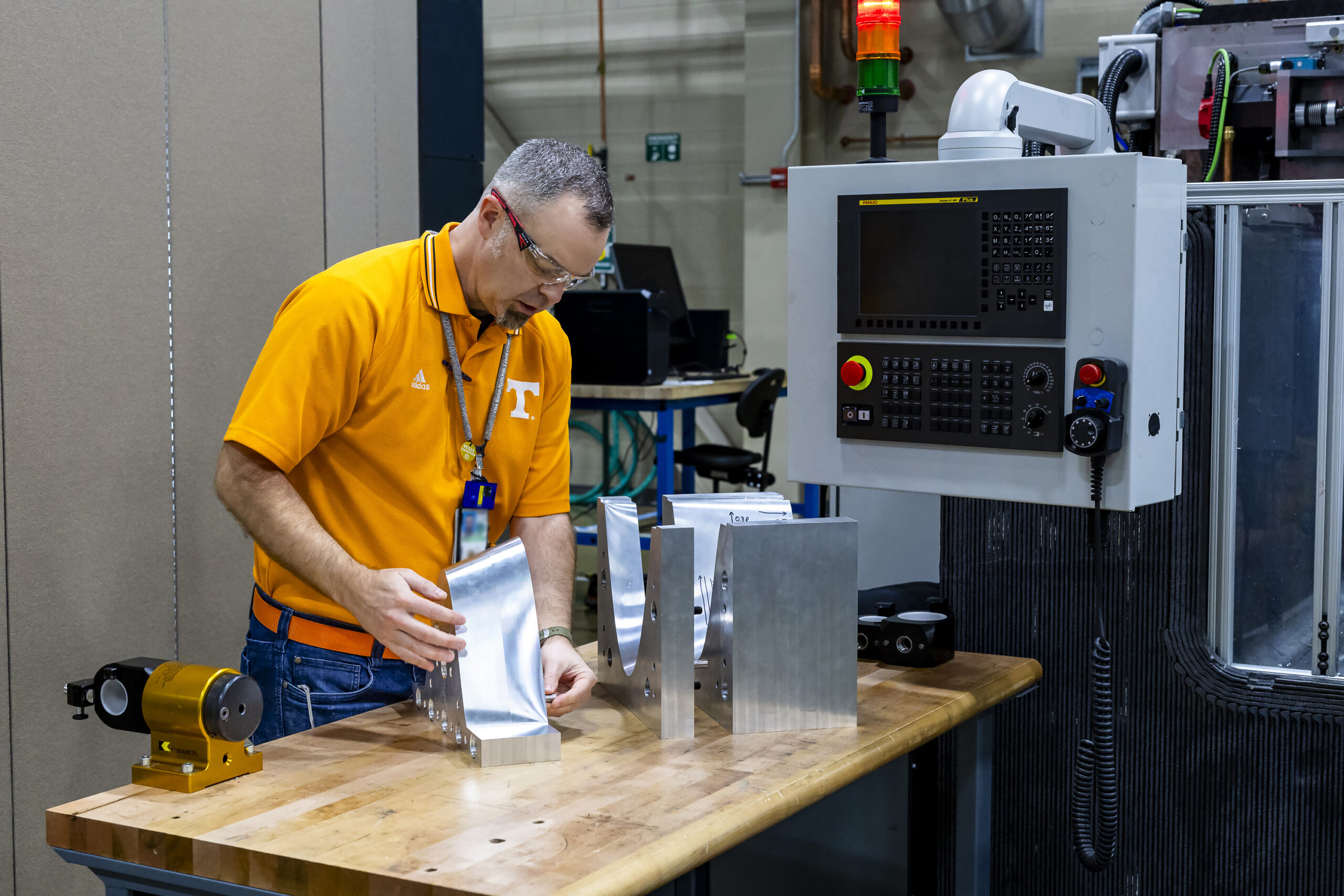

AI Streamlines Manufacturing from the Ground Up

Behind the scenes, the factories making these tools are getting smarter too. AI now watches over production lines, using predictive analytics to spot hiccups before they become disasters. For example, sensors on machines feed data to algorithms that spot patterns and forecast when a part might fail. McKinsey & Company’s research shows that AI in manufacturing can boost productivity by as much as 20%. That means less downtime, fewer wasted materials, and more consistent quality. Some factories are already using AI-powered robots that learn from every batch they make, getting better and faster with each run. The result? Better tools delivered quicker and with fewer defects, reshaping how companies meet the ever-growing demand for reliability.

Making Tools Friendlier and Smarter for Users

AI isn’t just for manufacturers; it’s making life easier for everyday users, too. Imagine augmented reality (AR) apps that overlay instructions onto your workbench, guiding you step-by-step through tricky assembly jobs. This kind of real-time feedback is a game-changer, especially for folks who aren’t professional mechanics. Tools with built-in AI can also sense how you’re using them and suggest better ways to get the job done, almost like having a skilled mentor looking over your shoulder. This reduces the time spent fumbling with instructions and helps cut down on costly mistakes, making advanced DIY projects accessible to more people than ever before.

AI-Powered Data Analytics: The Industry’s New Secret Weapon

Every use of a smart tool generates mountains of data—about how, when, and why people use them. With AI, companies can sift through this data to spot trends, figure out which features users love (or hate), and even predict what kinds of tools people will want next. Statista reports that the global big data analytics market is set to reach $274 billion by 2022, a sign that data-driven decision-making is now at the heart of the tool industry. Manufacturers are using this insight to fine-tune features, create targeted marketing campaigns, and launch tools that hit the sweet spot for both professionals and hobbyists. It’s almost like the tools themselves are whispering secrets back to their creators.

AI’s Role in Pushing for Sustainability

Today’s tool industry faces mounting pressure to go green, and AI is lending a powerful hand. Algorithms can figure out the most efficient ways to use raw materials, cutting down on waste and slashing energy bills. In some factories, AI tracks every drop of oil and every watt of electricity, making sure nothing is squandered. The World Economic Forum predicts AI could help cut global greenhouse gas emissions by 4% by 2030. That’s no small feat when you consider the millions of tools and machines being made worldwide each year. By optimizing supply chains, reducing scrap, and designing smarter, longer-lasting tools, AI isn’t just making work easier—it’s also making it more responsible.

Challenges and Hurdles on the Road to Smart Tools

Despite all the buzz, the road to a fully AI-powered tool industry isn’t exactly smooth. One major hurdle is the steep cost of upgrading factories and training workers to use these new systems. Smaller manufacturers, in particular, can struggle to keep up with the pace of change. Then there’s the issue of data privacy. With smart tools collecting so much information about how, where, and when they’re used, companies must walk a fine line between innovation and respecting user privacy. Ensuring robust cybersecurity measures is becoming just as important as making the tools themselves. These challenges mean that while AI offers big rewards, not everyone will be able to grab them right away.

The Future: Where AI and Tools Go from Here

Looking ahead, the blend of AI and tools shows no signs of slowing down. Robotics and automation are set to play an even bigger role, with machines that can not only build tools but also fix themselves and adapt to new products on the fly. As AI becomes more affordable and accessible, even small workshops could tap into its benefits. The line between user and machine will blur further, with tools that learn from their owners, anticipate their needs, and evolve over time. This could spark a new wave of creativity and innovation, changing not just how tools are made, but what it means to use them in everyday life.