- Avoid a Holiday Disaster with These Quick Repairs - June 4, 2025

- “These 5 DIY Wood Projects Are Trending Like Crazy Right Now” - June 2, 2025

- The Lazy Person’s Guide to Home Maintenance - May 31, 2025

Have you ever opened a dusty toolbox and wondered if your old, forgotten tools could shine again? It’s shocking how many people toss away perfectly usable tools just because they look rough or feel stiff. But beneath that rust and grime, those tools are just waiting for a second chance. Imagine the satisfaction of bringing them back to life, saving money, and feeling that spark of pride each time they work like new. Let’s dive into seven surprisingly simple but powerful ways to revive your old tools—and make them a joy to use once more.

Clean Your Tools Thoroughly

Cleaning is the first and often the most transformative step in reviving old tools. Over the years, dirt, grease, and rust can build up, making even the sturdiest tools hard to use and less effective. A gentle scrub with warm, soapy water can remove most surface grime, but for stubborn rust, a mix of vinegar and baking soda can work wonders. Many experts recommend soaking rusted parts overnight for best results. According to research by the American Society of Home Inspectors, regular cleaning can extend tool life by up to 50%, which means a simple cleaning routine can save you from costly replacements. After washing, it’s crucial to dry every metal surface thoroughly, as even a little leftover moisture can kick-start new rust. Imagine the transformation: from a tool caked with years of neglect to one that gleams in your hand, ready for action.

Sharpen Blades and Edges

Sharp tools aren’t just easier to use—they’re safer and much more effective. Dull blades can slip, snag, or even cause injuries, while a sharp edge cuts cleanly and predictably. Using a sharpening stone or a metal file, you can breathe new life into knives, chisels, pruners, or saws. For saw blades, a few careful strokes can restore that satisfying bite. The Woodworking Network reports that a well-sharpened blade can cut materials up to 30% faster than a dull one, making your work smoother and less tiring. Sharpening is a skill anyone can learn with a bit of patience, and the payoff is immediate. There’s something deeply satisfying about restoring a tool’s edge and feeling it glide through wood or metal as if it were brand new.

Replace Worn Parts

Sometimes, all that stands between an old tool and peak performance is a single worn-out part. Handles crack, blades chip, and springs can lose their tension, but most of these can be replaced without much fuss. Many hardware stores and manufacturers offer replacement parts for common tools, making repair a budget-friendly option. Swapping out a tired saw blade or a broken handle can make a tool feel factory-fresh. The National Association of Home Builders reports that replacing worn parts can extend a tool’s lifespan by an average of 20%. Instead of tossing a favorite hammer or screwdriver, consider a quick repair. The emotional reward of fixing something you thought was lost is often just as valuable as the savings.

Lubricate Moving Parts

Many tools rely on moving parts—think pliers, wrenches, or ratchets—and over time, these joints can become stiff or squeaky. A few drops of machine oil, silicone spray, or even traditional grease can work miracles, restoring smooth, effortless motion. Without lubrication, friction builds up, causing parts to grind, seize, or wear out much faster. The Machinery Lubrication Institute found that proper lubrication can reduce wear by up to 80%, which is staggering when you think about the cost of replacing tools. Make it a habit to oil moving parts every few months, especially after heavy use or a deep clean. The difference is often immediate—suddenly, that old pair of pliers feels as nimble as the day you bought it.

Store Tools Properly

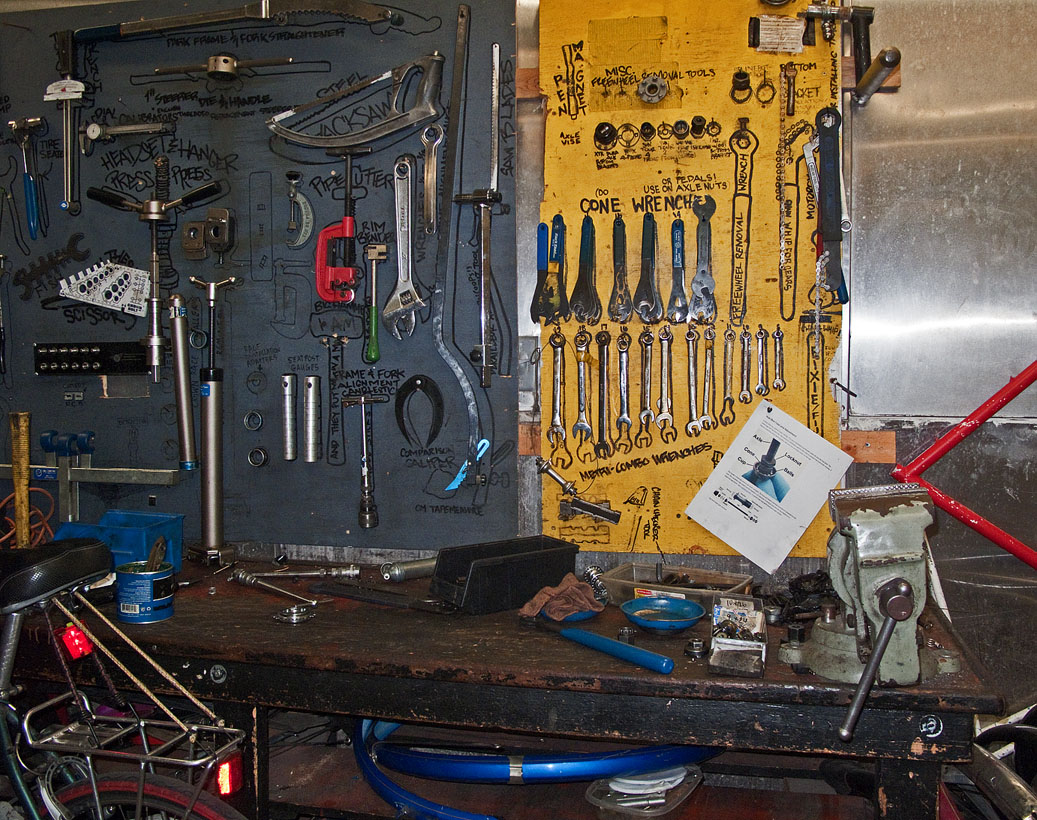

How you store your tools can mean the difference between decades of reliable service and an early trip to the scrap heap. Tools left in damp garages or sheds are magnets for rust and corrosion. Keeping them dry, organized, and protected is crucial. Toolboxes, wall-mounted pegboards, and even magnetic strips can keep everything in its place and off the floor. The Home Improvement Research Institute found that properly stored tools last up to 30% longer than those left exposed. Adding silica gel packs or a small dehumidifier to your storage area can help fight moisture. Labeling shelves or drawers also makes it easier to find what you need, reducing the temptation to leave tools out in the open. Good storage habits not only protect your investment but also make you feel more organized and in control.

Use the Right Tools for the Job

It’s tempting to grab whatever’s handy when you’re in a hurry, but using the wrong tool can do real damage. For example, using a wrench as a hammer can warp it, while using a flathead screwdriver on a Phillips screw can strip the tip. The National Institute of Standards and Technology found that using the right tool improves efficiency by up to 40%. This means less frustration, fewer broken tools, and safer, faster work. Always read manufacturer instructions, and take a moment to consider whether you have the best tool for the task. It might seem like a small detail, but the right match between tool and job keeps your gear—and your projects—looking sharp.

Regular Maintenance Checks

Even the best tools need a little attention now and then. Set aside time every few months to inspect your collection for rust, cracks, or loose parts. Routine maintenance can catch small problems before they become big, expensive headaches. The American Tool Association states that tools that receive regular tune-ups can last up to 50% longer. Create a simple maintenance log or checklist to keep track of when each tool was last inspected, cleaned, or repaired. This small habit can save you significant money and stress in the long run. It’s like taking your car for an oil change—a little effort today can prevent a breakdown tomorrow.

Remove Rust with Modern Methods

Rust is one of the biggest enemies of any metal tool, but today’s rust removal methods are both gentle and effective. In addition to the classic vinegar soak, there are specialized rust erasers and gels available in hardware stores. Some use chemicals that convert rust into a stable compound, making it easy to wipe away. Wire brushes and steel wool are still valuable, but modern products can speed up the process and reduce the risk of damaging the tool’s surface. Restoring a rusty wrench or spade can feel like performing a magic trick, revealing shiny metal where there was only orange corrosion before. It’s not just about looks—removing rust makes tools stronger and safer to use.

Tighten Loose Screws and Bolts

Over time, the vibrations from heavy use can loosen screws, bolts, and nuts on your tools. Loose hardware can make a tool feel wobbly or even dangerous. Take a few minutes to check and tighten every fastener you can find. This simple step can restore the solid feel of a hammer, pliers, or even larger equipment like a vice or drill press. If you find stripped threads, a thread locker or replacement screw can provide a long-lasting fix. This attention to detail makes a big difference in both the safety and performance of your tools, ensuring they feel steady and reliable in your hand.

Upgrade Handles for Comfort and Safety

Many older tools have wooden or plastic handles that become cracked, splintered, or slippery over time. Upgrading to a new handle—or even wrapping the old one with a comfortable grip—can make a world of difference. Replacement handles are widely available for hammers, axes, and garden tools, and installing one usually takes less than an hour. For smaller tools, adding a rubber grip or tape can boost comfort and reduce fatigue. A sturdy, comfortable handle not only prevents blisters but also helps you control the tool more precisely. This simple upgrade can revive even the most battered-looking piece of equipment, making it a pleasure to use again.